Fuel Gas Conditioning Applications

Achieve gas BTU specification by reducing heavy hydrocarbon or inert content

Fuel gas conditioning for power equipment such as gas engines and gas turbines can be addressed by Air Liquide Advanced Separations' (ALaS) PEEK-Sep membrane systems. The heating value of the gas is adjusted to the target specification by removing C2 + hydrocarbons. In some cases, PEEK-Sep membranes are used to increase the heating value of the gas by removing an excessive amount of carbon dioxide or nitrogen. ALaS' flexible process design addresses diverse customer needs for fuel gas conditioning that improves engine performance, reduces maintenance and increases uptime.

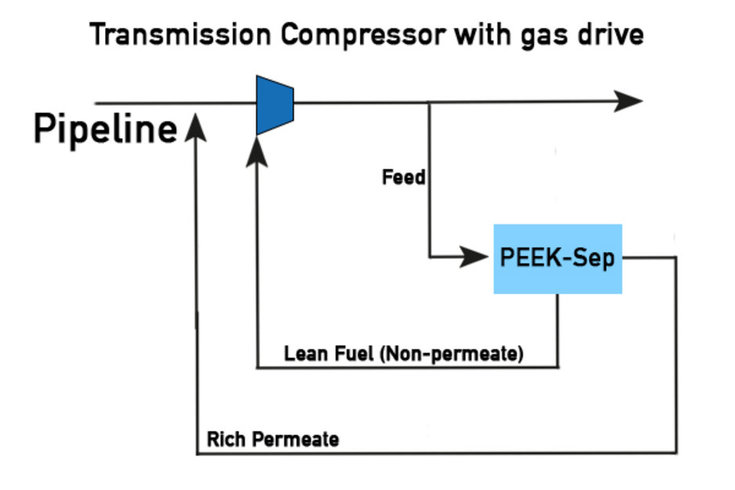

Compressor Station Conditioning

An example of heavy hydrocarbon removal from pipeline gas is shown in the figure below. If the operation of gas driven power equipment is affected by heavy hydrocarbons in the pipeline gas, upgrading of the gas, utilizing the PEEK-Sep membrane system allows improved operation with no loss of hydrocarbon values. A compact membrane skid is the only add on equipment required.

-

Membrane Units for Fuel Gas Conditioning Heavy Hydrocarbon and Water Removal from Natural Gas

Download the document PDF (2.6 MB)

Advantages

- Dehydrates the gas in addition to removing heavy hydrocarbons

- Removes carbon dioxide and hydrogen sulfide in addition to removing heavy hydrocarbons

- Hollow fiber membrane configuration provides for small system footprint and reduced operator interface

Request information

Raj Palla, Director - Natural Gas

Contact by phone +1 630-487-1270

Related applications

Air Liquide Advanced Separations (ALaS) manufactures a comprehensive line of membrane products for natural gas and associated petroleum gas treatment.