Helium Recovery Applications

Membrane technology for helium recovery

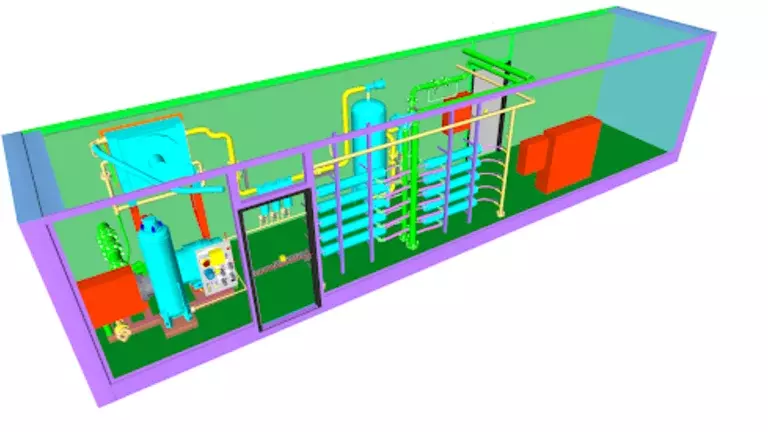

Complete modular solutions for helium purification of raw gas from well to tube trailers

Our Technology

The Air Liquide Modular Helium Purifier is fully customizable and provides a comprehensive solution with the ability to remove CO2, CH4, H2S, N2, Ar, O2, H2 and moisture, producing purified helium for the customer. The core of the solution typically includes multiple membrane stages combined with PSA technology.

Membranes

Air Liquide membranes are based on hollow fiber technology for the recovery of helium from natural gas or nitrogen rich gases. Hollow fiber membranes provide the most efficient means of selectively separating gases due to the high surface area available for gas permeation per unit volume. In a raw gas feed stream typically consisting of methane and other hydrocarbons, nitrogen, other impurities and helium, helium’s very simple atomic structure allows it to selectively permeate and enrich in concentration much faster than the other components. When a natural gas stream containing helium is fed at pressure to a hollow fiber membrane, helium is selectively concentrated in the permeate stream, leaving a helium-depleted methane-rich stream as the residue stream.

PSA

Pressure Swing Adsorption (PSA) technology consists of multiple vessels, each packed with adsorbent beds that perform a different function. In the first step, almost all components except helium are removed from the stream, producing a high purity helium product which is then further purified in multiple steps by changing the pressure of the adsorbent bed. Many additional steps can be integrated as needed such as compression, water removal, hydrocarbons removal, hydrogen sulfide (H2S) removal and hydrogen removal in order to achieve the desired purification.

Helium recovery from Lighter Than Air (LTA) ships

LTA ships for merchandise and people transportation are gaining a lot of traction in the current environment because it can be a sustainable alternative for air transportation. Such ships are typically filled with helium for buoyancy. This helium is getting polluted with air over time. At some point the helium concentration inside the ship is too low to fly. Given the high value of helium, it is highly recommended to use a helium purifier in order to purify the helium instead of replacing the whole load. Air Liquide has developed a standard, container size, membrane purifier that can be easily hooked up to airships for purification in record time with very small losses using Air Liquide’s best in class membranes. Air Liquide can provide a complete system with the fastest delivery that meets your specific project needs.

Overall process integration

Air Liquide has developed patented methods and technologies for efficient helium processing. Air Liquide guarantees the performance of its units and delivers a highly reliable helium source for the customer. The complete solution is constructed with skid-mounted units which are easily transported to the site and then connected in the field.

-

Helium Brochure

Download the document PDF (1.18 MB)

Request information

Kirsten O'Sullivan, Senior Manager, Hydrogen & Helium Business Unit

Contact by phone +1 262-930-4395