Oil & Gas Applications

Fixed or mobile nitrogen systems for oil and gas applications

Download our brochures

-

Small N2 Production Systems

Download the document PDF (459.72 KB) -

Large N2 Production Systems

Download the document PDF (454.26 KB) -

Offshore Mobile N2 Production Unit

Download the document PDF (731.98 KB)

Small N2 Production System

Air Liquide small nitrogen (N2) production system is a fully integrated system that provides a continuous supply of N2 as demand changes. It is a reliable, low-cost N2 supply solution when cryogenic purity is not required. Small integrated N2 standard systems offers plug and play installation with full purity insurance. Most generally recommended for offshore operation and but also for maritime installation.

Technical Features:

- Purity range 95% to 99.9%

- Flow rates 10 Nm3 / hr to 400 Nm3 / hr

- Maximum operating temperature 55°C

- Moisture Content < 10 ppm (< 1 ppm optional)

- Oil Content < 0.003 ppm (not measurable)

- Particulates < 0.01 micron

- Power:

- 60 HZ: 440 / 460v, 3 phase

- 50 HZ: 380 / 415v, 3 phase

Standards:

- Pressure: ASME BPVC VIII Div1

- Electrical IEC or NEC

- ISO 9002 certified process

- International certification available (ABS, DNV) - Hazardous (ATEX 2 / Class I Div 2) upon request

- Systems available with / without air compressor – Air / N2 receiver upon customer request

Large N2 Production System

Air Liquide large N2 production system is a fully integrated system with large capacity that provides continuous supply of nitrogen as demand changes. It is a reliable, low cost supply solution when cryogenic purity is not required. Large integrated N2 standard systems offers plug and play installation with full purity assurance. Well adapted for offshore and maritime environment.

Technical Features:

- Purity range 95% to 99.9%

- Flow rates 400 Nm3 / hr to 13,000 Nm3 / hr

- Maximum operating temperature 55°C

- Moisture Content < 10 ppm (< 1 ppm optional)

- Oil Content < 0.003 ppm (not measurable)

- Particulates < 0.01 micron

- Power:

- 60 HZ: 440 / 460v, 3 phase

- 50 HZ: 380 / 415v, 3 phase

Standards:

- Pressure: ASME BPVC VIII Div1

- Electrical IEC or NEC • ISO 9002 certified process

- International certification available (ABS, DNV) - Hazardous (ATEX 2 / Class I Div 2) upon request

- Systems available with / without air compressor – Air / N2 receiver upon customer request

Mobile N2 Production Units

Ideally suited for pipelines and well services activity - Air Liquide mobile nitrogen production units could be used for on shore and offshore activities. The units can be available for sale or rental.

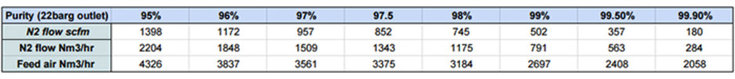

Performance:

- Up to 13,000 Nm3/h - 8000 scfm at 95% purity available for sale upon request

- Up to 2200 Nm3/h - 1400 scfm at 95% purity available for rental standard unit - other units available upon requests

- Maximum operating temperature 55°C

- Delivery Pressure 22 bar - 319 psi

- Moisture Content < 10 ppm (< 1 ppm optional)

- Oil Content < 0.003 ppm (not measurable)

- Particulates < 0.01 micron

Technical Features:

- Power: 60 Hz, 460V, 3 phase, 30 Amp, 60 kW

- 20" container in standard: L 6096mm, W 2438mm, H2859mm

- Typical weight: Up to 14,000 kg - 8400 kg for standard rental unit

- Electrical fan ventilated, general lighting, ambient oxygen analyzer, painting standard for offshore environment

Standards:

- Pressure: ASME BPVC VIII Div1

- Electrical IEC or NEC

- ISO 9002 certified process

- Rig safe - Hazardous (ATEX 2 / Class I Div 2) upon request

- Portable units are containerized to meet offshore DNV 2.7-1 standard

- CSC certification

- Systems available with / without air compressor – Air / N2 receiver upon customer request

Request information

Paul Burgin, Director, Nitrogen Membrane Products

Contact by phone +44 (0) 7771 334763

Related applications

Air Liquide Advanced Separations (ALaS) membranes generate an optimal balance of productivity and recovery for onsite nitrogen supply.